Lub tshuab hluav taws xob mobile txee yog ib qho ntawm cov khoom siv ceev ceev. Nws yog qhov kev tswj hwm niaj hnub niaj hnub ua ke nrog lub khoos phis tawj sab sauv WMS warehouse tswj software, import PLC, zaus hloov pauv, sensor, 7-nti kov npo, Android ntse mobile davhlau ya nyob twg sau, RFID, bar code technology system thiab ntse cia ua haujlwm. Nws muaj peev xwm khaws cia siab, muaj kev tiv thaiv kev tiv thaiv, thiab muaj qee yam kev tiv thaiv av qeeg! Kev nyab xeeb yog siab heev, thiab qhov qhib ntawm channel kuj ceev dua. Lub kaw lus tsuas xav tau ib qho channel, thiab qhov chaw siv qhov chaw siab heev. Lub cev muaj zog tsav lub nqa trolley, thiab lub trolley yog muab tso nrog beam hom txee thiab cantilever txee. Cov kev cai hloov pauv ceev ceev ua rau cov rhawv tsis tshua muaj kev ruaj ntseg txij thaum pib mus rau braking, thiab kev nyab xeeb yog lav. Lub trolley yog tsav los ntawm lub cev muaj zog, thiab pallet khib, cantilever khib, thiab lwm yam yog muab tso rau ntawm lub trolley. Kev tswj hwm qhov sib txawv ntawm qhov ceev ua rau lub khib kom paub txog automation, kev txawj ntse, kev nyab xeeb thiab kev ntseeg tau txij thaum pib mus rau braking. Raws li daim ntawv taug qab, cov khib nyiab tuaj yeem muab faib ua ob hom: hom kev taug qab thiab hom tsis siv. Cov khib nyiab no muaj kev hloov pauv ntau zaus, uas tuaj yeem tswj qhov nrawm thaum tsav tsheb thiab nres kom tsis txhob muaj cov khoom ntawm cov khib nyiab los ntawm kev co, tilting lossis pov tseg. Lub photoelectric sensor rau qhov chaw thiab lub iav brakable lub cev muaj zog kuj tau nruab rau ntawm txoj haujlwm tsim nyog, uas txhim kho qhov chaw ua haujlwm. Daim ntawv thov ntawm cov txee hluav taws xob yuav tsum muaj kev nkag siab tag nrho ntawm qhov chaw khaws khoom, cov khoom khaws cia, cov txheej txheem nkag thiab lwm yam los tsim cov khoom siv logistics tsim nyog rau kev daws teeb meem.

Lub txee hluav taws xob txawb tau muab tso rau ntawm cov hlua khi, cov hlua hauv av yog qhov ruaj khov thiab du, thiab cov txheej txheem kev teeb tsa muaj ntau yam. Feem ntau ntawm lawv tau txais cov cuab yeej sib nqus kev taw qhia ntawm cov neeg nqa khoom tsis muaj neeg siv, thiab muaj cov khoom siv thaum muaj xwm ceev. Kev nyab xeeb yog siab heev. Nws muaj ob peb txoj hauv kev, chav tsev loj loj thiab qhov chaw siv qhov chaw siab, uas yog peb npaug ntawm cov txee zoo tib yam. Nws tuaj yeem siv nrog pallets los khaws cov khoom hnyav, tab sis tus nqi kuj yog siab heev.

Lub hauv paus ntsiab lus thiab kev tiv thaiv kev nyab xeeb ntawm hluav taws xob txawb txee

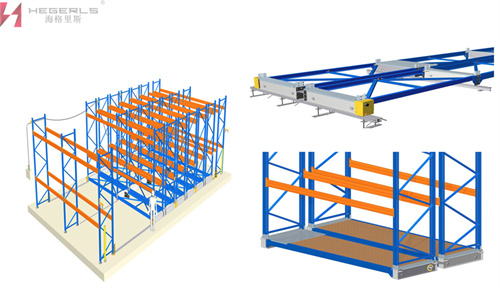

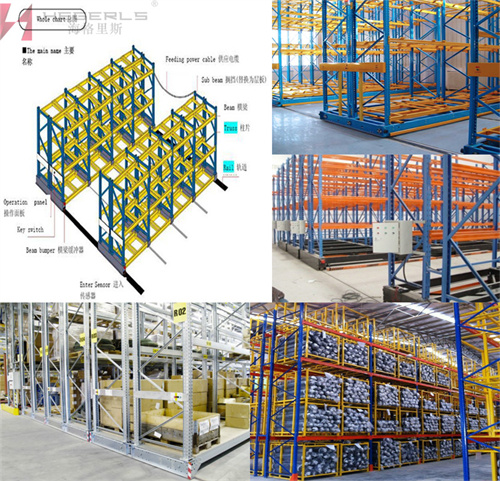

Lub hauv paus ntsiab lus: ob kab rov qab-rau-rov qab rhawv tau nruab rau ntawm lub phaj hauv qab daus hauv ib pab pawg, uas tuaj yeem npaj ua ntau pawg. Txhua lub chassis yog muab nrog ntau lub chais, thiab txhua lub chassis yog muab nrog ntau lub cav tsav. Los ntawm nias lub khawm tswj, lub tsav tsav tsav tag nrho cov phaj hauv qab thiab cov khoom ntawm lub txee los ntawm cov saw tsav, thiab txav mus rau ob lossis ntau qhov kev taug kev hauv av (los yog cov hlau nplaum qub sib txawv - lub ntuj khiav), Yog li ntawd lub forklift tuaj yeem nkag mus rau qhov chaw txav mus rau cov khoom nkag.

Kev tiv thaiv kev nyab xeeb: lub cev muaj zog reducer thiab lub tswb ntsuas cov cuab yeej kuj tau nruab rau ntawm lub chassis, uas tuaj yeem tsis tsuas yog txhim kho qhov tseeb ntawm qhov chaw ntawm cov khib nyiab, tab sis kuj tswj kev ceev ntawm kev tsav tsheb thiab nres, txhim kho kev nyab xeeb ntawm kev mus ncig, thiab tiv thaiv. cov khoom ntawm lub khib los ntawm kev co, tilting lossis pov tseg; Txhua chav tsev txav tau nruab nrog lub cev muaj zog hloov pauv ceev tswj, qhia kev tsheb ciav hlau nrhiav pom ntawm ob sab, ntau theem txee lub sijhawm tswj xyuas thiab lwm yam khoom siv los txheeb xyuas cov teeb meem txawv teb chaws ntawm kev khiav thiab tswj qhov kev ncua deb ntawm cov txee txav;

Lub cev muaj zog overcurrent thiab overload tiv thaiv kom paub txog kev tiv thaiv ntawm lub tshuab tsav; Lub kaw lus tau nruab nrog chav tsev txawb txee pib ceeb toom muaj nuj nqi, kev ua haujlwm flashing lub teeb sai, pib thiab ua haujlwm buzzer ceeb toom ua haujlwm kom paub txog kev tiv thaiv kev nyab xeeb ntawm cov neeg ua haujlwm thiab khoom siv.

Ua hauj lwm hauv paus ntsiab lus ntawm hluav taws xob mobile txee

Qhov hnyav-lub luag haujlwm txawb khib tau hloov zuj zus los ntawm lub luag haujlwm hnyav pallet khib. Nws muaj ib tug liab qab qauv. Txhua ob kab ntawm racks yog muab tso rau ntawm lub hauv paus. Lub hauv paus yog nruab nrog lub log mus ncig thiab khiav raws txoj kev. Lub chassis yog nruab nrog motors, reducers, tswb thiab sensing li. Lub kaw lus tsuas yog yuav tsum tau teeb tsa 1-2 raws, thiab qhov chaw siv tus nqi siab heev. Cov qauv zoo ib yam li lub teeb thiab qhov nruab nrab ntawm lub xov tooj txawb racks, uas txawv ntawm cov khoom hnyav hnyav. Cov khoom yog thauj los ntawm forklift tsheb. Txoj kev feem ntau yog hais txog 3M. Nws yog tsuas yog siv nyob rau hauv qhov chaw uas qhov chaw warehouse tsis loj thiab qhov chaw yuav tsum tau siv rau qhov siab tshaj plaws. Nws yog tsim rau machinery manufacturing thiab lwm yam lag luam.

Cov yam ntxwv ntawm hluav taws xob mobile txee system

1) Nws yog tsim rau warehouses nrog tus nqi siab ntawm ib cheeb tsam, xws li txias cia, tawg-pov thawj warehouse, thiab lwm yam.

2) Tsis muaj saw tsav, txuag hluav taws xob ntau dua, txhim khu kev qha ntau dua.

3) Kev khaws cia ntau dua, cov channel tsawg dua, tsis tas yuav nrhiav cov channel nkag mus rau cov khoom.

4) Piv nrog cov txee zoo tib yam, kev siv cov av tuaj yeem nce li ntawm 80%.

5) Kev xaiv lub peev xwm ntawm lub txee hluav taws xob hluav taws xob tuaj yeem yog li 100%.

6) Nws yog qhov yooj yim hauv cov qauv, muaj kev nyab xeeb thiab txhim khu kev qha, thiab tuaj yeem txav tau thaum lub zog tsis ua haujlwm. Piv nrog rau cov txee ruaj ruaj, tsuas yog lub trolley hauv qab yog ntxiv, thiab cov qauv ntawm lub trolley yog qhov yooj yim heev. Tsis muaj qhov nyuaj thiab cov khoom siv, thiab kev ua haujlwm thiab kev saib xyuas yog yooj yim thiab yooj yim. Txoj kev khiav hom muaj lub peev xwm loj, thiab qhov hnyav tshaj plaws ntawm txhua chav tuaj yeem yog 32t. Txoj kev tshwj xeeb yog siv los yaug nrog hauv av thiab tuav lub tiaj tus hauv av. Kev tsim kho tsis siv neeg yog yooj yim dua thiab yooj yim dua, thiab tsis tas yuav ua rau cov av uas twb muaj lawm.

7) Nws tsuas yog yuav tsum tau nruab nrog lub forklift mus rau pem hauv ntej los yog lub forklift counterweight yuav tsum tau siv, thiab cov kev cai rau kev ua haujlwm forklift tsawg.

8) Zoo seismic tsis kam thiab ruaj khov: cov kab txav tsis muaj kev ua haujlwm tuaj yeem muab tso ua ke, uas nthuav dav qhov chaw tso chaw thiab txhim kho tag nrho seismic tsis kam thiab ruaj khov. Cov khoom ntawm lub txee tsis yooj yim rau zawv zawg vim lawv nyob sib ze.

Yuav ua li cas xaiv cov khoom tsim nyog ntawm hluav taws xob txawb txee?

1) Seb tus neeg muag khoom muaj nws tus kheej tsim, kev tsim kho thiab pab pawg ntawm cov khoom siv automation;

2) Kev siv cov khoom txee. Vim tias tus qauv tsim ntawm lub txee hluav taws xob hluav taws xob sib txawv ntawm cov khoom thauj thiab deflection cov cai ntawm cov txee ib txwm siv, cov neeg siv khoom yuav tsum paub txog cov qauv tsim thiab qhov txawv ntawm qhov sib txawv ntawm ob tus neeg muag khoom.

3) Lub txee hluav taws xob hluav taws xob yog qhov chaw cia khoom siab, uas yuav tsum tau ua hauv av. Yog tias cov av tsis tsim nyog, nws yuav tsum tau rov ua dua. Hauv pem teb tuaj yeem ua tau tom qab kev sib tham ntxaws nrog tus neeg muag khoom ua ntej yuav khoom.

Hegerls chaw tsim tshuaj paus

Haigris cia txee chaw tsim tshuaj paus yog cov chaw tsim khoom txee hauv Suav teb, nrog ntau tshaj 20 xyoo ntawm kev tsim khoom, R & D thiab kev tsim khoom. Nws yog lub txee lub teeb yuag, lub txee nruab nrab hnyav, lub txee hnyav hnyav, lub txee cantilever, lub txee los ntawm lub txee, lub txee rau cov menyuam, xovxwm hauv txee, txee txawb, txee txee, qhov chaw muag khoom txee. (rau 4S cov khw muag khoom) Nws yog ib lub tuam txhab loj loj tshwj xeeb hauv kev tsim khoom thiab kev ua haujlwm ntawm cov khoom siv peb sab warehouse thiab cov khoom siv peripheral (cia racks, stacking racks, steel pallets, yas pallets, cia tawb, thawv khoom, handcarts, ntsiag to trolleys, nce tsheb, logistics trolleys, loading trolleys, hydraulic lifting platforms, hydraulic boarding txuas hniav, phau ntawv hydraulic pallet carriers, self-propelled electro-hydraulic loading thiab unloading forklifts, thauj rollers, thiab lwm yam), cov ntaub ntawv raw siv rau cov txee yog standard high-quality carbon steel, uas yog check, khoom thiab xeb dawb, thiab xyuas kom meej cov khoom zoo los ntawm qhov chaw. Nyob rau tib lub sijhawm, Tigris rhawv yog welded nrog oxygen shielded vuam, uas muaj qhov zoo tawg tsis kam, vuam me me deformation thiab zoo nkauj zoo nkauj. Txhua kem thiab kab ntawm lub txee yog tsim thiab txiav los ntawm peb cov neeg ua haujlwm nrog kev tshaj lij thev naus laus zis, txhawm rau xyuas kom meej qhov loj ntawm lub txee. Kev tshaj lij tshuaj tsuag pretreatment, tshem tawm roj, tshem tawm xeb, phosphating, hmoov txau, thiab tom qab ntawd ci hauv qhov cub kub. Txhua kauj ruam yog rau cov khoom txee zoo meej. Lub Hoobkas muaj peev xwm ntau lawm ntawm lub chaw tsim khoom txee, thiab tuaj yeem kho ntau yam khoom ntim raws li koj xav tau. Ntxiv mus, hluav taws xob movable txee uas tsim los ntawm hagris muaj kev nyab xeeb thiab txhim khu kev qha.

Vim li cas thiaj muaj kev nyab xeeb thiab ntseeg tau hais tias haigris hluav taws xob txawb txee?

1) Thaum xaiv cov cuab yeej tswj hwm, hagris siv cov khoom lag luam qib tseem ceeb. Cov khoom ua tau raws li qhov xav tau ntawm ib puag ncig kub, av noo thiab kev tiv thaiv. Hauv kev tsim ntawm kev ua haujlwm ntawm software system, peb xav txog qhov yooj yim ntawm cov neeg siv khoom thiab kev siv yooj yim, uas ua rau muaj kev sib raug zoo ntawm software system. Tsis tas li ntawd, peb muab ntau yam software thiab kho vajtse interlocking tiv thaiv ntsuas raws li qhov ua tau thiab cov lus qhia ntxaws ntxaws.

2) Lub tshuab hluav taws xob txawb hluav taws xob muaj ntau qhov chaw nres tsheb thaum muaj xwm ceev.

3) Lub txee txawb hluav taws xob muaj ntau yam kev tiv thaiv, xws li overvoltage, overcurrent, overload, overheating, overtime, thiab lwm yam.

4) Lub tshuab hluav taws xob mobile txee muaj kev tiv thaiv kev ntsuas. Lub infrared photoelectric tiv thaiv muaj nuj nqi yog teem nyob rau hauv kab rov tav thiab ntsug cov lus qhia ntawm txhua ob rhawv. Thaum lub sijhawm ua haujlwm ntawm lub rhawv, yog tias muaj ib qho khoom nkag mus, lub kaw lus yuav cia li nres thiab muab lub tswb nrov nrov.

5) Lub tshuab hluav taws xob txawb khib nyiab tau poob khoom tiv thaiv. Thaum lub sijhawm ua haujlwm ntawm lub kaw lus, yog tias cov khoom raug thaiv ntawm ob lub racks, lub kaw lus yuav cia li nres thiab pib lub tswb nrov thiab pom kev ua haujlwm.

Post lub sij hawm: Aug-16-2022