Nyob rau hauv xyoo tas los no, nrog rau kev loj hlob sai ntawm kev lag luam logistics, tais hom plaub-txoj kev shuttle tsheb tau siv dav hauv kev lag luam xws li hluav taws xob, khoom noj khoom haus, tshuaj, thiab cov saw txias, tshwj xeeb tshaj yog nyob rau hauv txias chain logistics scenarios. Tam sim no, cov cuab yeej muaj peev xwm ua haujlwm nyob rau hauv ib puag ncig ntawm -20 ℃ to -25 ℃, tshwj xeeb tshaj yog nyob rau hauv cov saw txias txias hauv qab -18 ℃. Kev siv plaub-txoj kev tsheb thauj mus los rau kev khaws cia tuaj yeem txhim kho qhov chaw siv tau zoo, Thiab nws tuaj yeem txhim kho ib puag ncig ntawm thaj chaw ua haujlwm, ua rau kev ua haujlwm ntawm cov neeg ua haujlwm zoo dua. Daim ntawv thov tag nrho cov xwm txheej tau ua tiav, thiab cov kev pabcuam tseem ceeb tau ua tiav hauv qee qhov kev lag luam. Nws muaj peev xwm los lis X-axis thiab Y-axis cov ntaub ntawv, nrog kev hloov pauv siab, tshwj xeeb tshaj yog tsim rau cov khoom lag luam tsis tu ncua, kev cia siab ceev, thiab tseem tsim nyog rau kev ua haujlwm hom nrog ntau cov khoom specifications thiab tsawg dua batches.

Raws li cov khoom lag luam txheem, lub tais hom plaub-txoj kev shuttle tuaj yeem hloov nrog ib leeg, thiab txhua lub tsheb plaub-txoj kev tuaj yeem ua haujlwm txuas ntxiv mus ua haujlwm ntawm cov teeb meem plaub-txoj kev tsheb. Tus naj npawb ntawm plaub-txoj kev tsheb yog txiav txim los ntawm kev sib xyaw ua ke ntawm cov khoom xws li qhov tob ntawm txoj kab ntawm lub rhawv, tag nrho cov khoom ntim, thiab qhov zaus ntawm kev ua haujlwm sab hauv thiab sab nraud. Nrog rau kev txhim kho txuas ntxiv ntawm kev tsim ontology, plaub-txoj kev tsheb thauj mus los rau cov pallets tau maj mam dhau los ua cov neeg txawj ntse tuav. Nws cov kev ua haujlwm tau zoo thiab kev hloov pauv tau zoo heev, thiab nws daim ntawv thov tsis txwv rau khaws cov khoom ntawm cov txee. Nws tuaj yeem siv rau hauv cov xwm txheej xws li kev tuav pov hwm thiab khaws khoom, uas ua rau muaj kev nyuaj siab ntawm kev teem sijhawm.

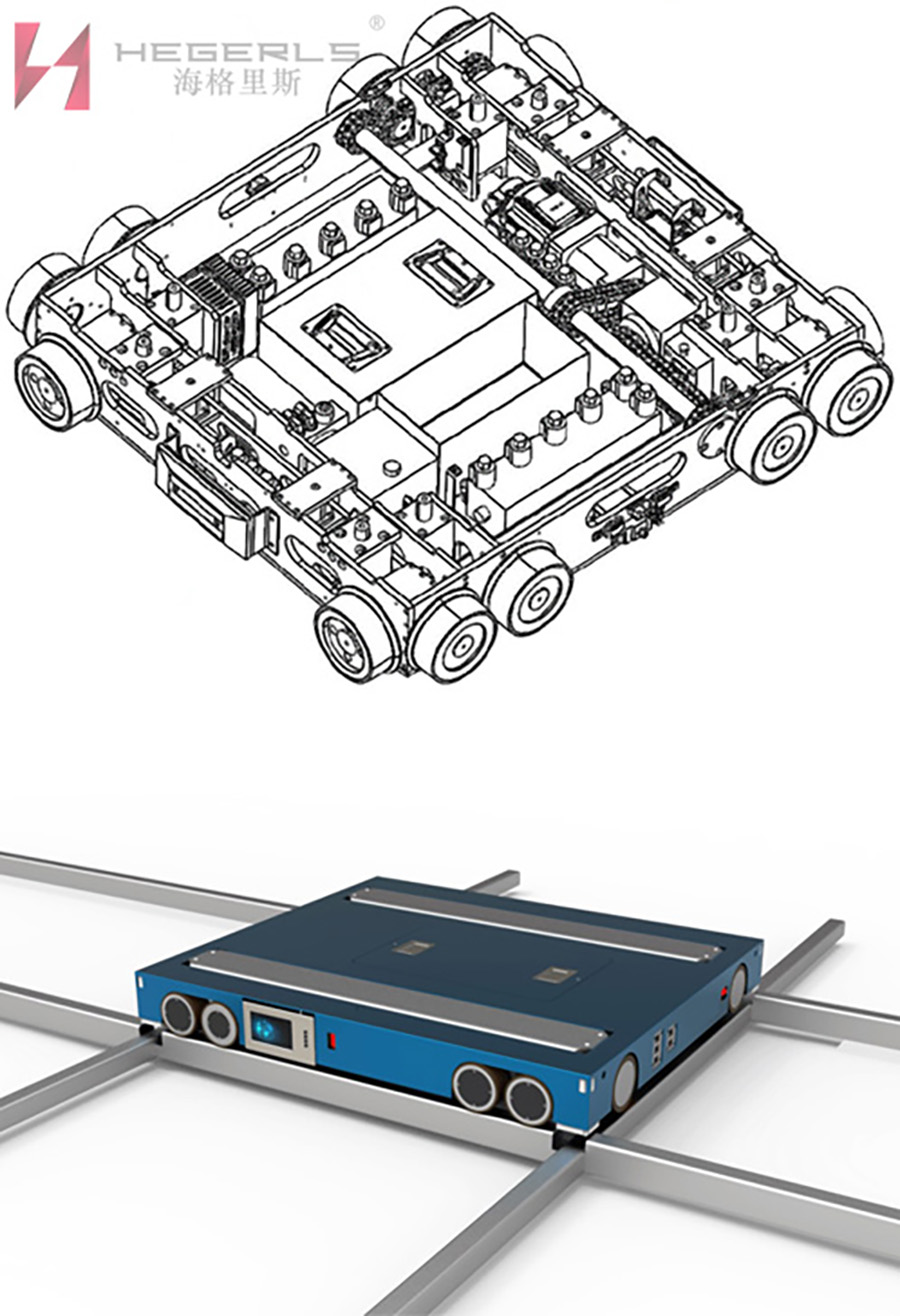

Lub txias cia series ntse tais plaub-txoj kev shuttle tsheb launched los ntawm HEGERLS txais ib lub teeb yuag tsim, optimizes tus neeg kho tshuab qauv, thiab ntxiv low-temperature tiv thaiv tsim rau hluav taws xob Cheebtsam nyob rau hauv tag nrho cov tsheb tsim. Cov kev tswj hluav taws xob thiab cov khoom siv tseem ceeb yog tag nrho ua los ntawm thawj qib qib qis-kub cov hlwb, tsis tshua muaj hluav taws xob txawv teb PLCs, thiab cov tshuab hluav taws xob; Txhawm rau kom muaj kev ruaj ntseg ntawm lub kaw lus, lub tsheb plaub-txoj kev shuttle thiab txias saw hoist undergo ib 3 * 24-teev kev ua tau zoo nyob rau hauv lub Hoobkas qhov kub thiab tsis kub humidity kuaj ua ntej tawm hauv lub Hoobkas, thiab cov tub ntxhais Cheebtsam undergo ib 7 * 24. - teev ua haujlwm kuaj. Lub Hagrid HEGERLS tray hom plaub-txoj kev shuttle system kuj muaj cov txheej txheem kev tswj hwm qhov chaw thauj khoom (WMS) thiab cov khoom siv sijhawm teem sijhawm (WCS). Cov software no tsis txawv ntawm AS / RS ib txwm muaj, tab sis qhov txawv yog lub sijhawm teem sijhawm rau tsheb thauj mus los, uas AS / RS tsis muaj. Lawv tuaj yeem ua kom ruaj khov thiab ua haujlwm tau zoo ntawm txhua qhov system. Txhawm rau kom tsis txhob tos rau lub tais hom plaub-txoj kev tsheb thauj mus los thiab lub elevator thaum lub sijhawm ua haujlwm, lub cache conveyor kab yog tsim los ntawm lub elevator thiab cov txee. Ob lub tais hom plaub-txoj kev shuttle tsheb thiab lub elevator muab cov tais rau hauv cache conveyor kab rau kev hloov pauv, yog li txhim kho kev ua haujlwm.

HEGERLS txias cia tais plaub-txoj kev shuttle kuj tuaj yeem ua haujlwm nyob rau hauv qhov kub ntawm 0 ~ -25 ℃, seamlessly txuas WCS warehouse control system thiab WMS warehouse management system. Tom qab tau txais cov lus qhia ua haujlwm los ntawm WMS, AI algorithm optimization tuaj yeem ua tiav raws li qhov xwm txheej khaws cia ntawm cov khoom, thiab qhov chaw khaws cia thiab kev thauj mus los tuaj yeem npaj tsim nyog kom ua tiav qhov zoo ntawm qhov chaw cia, txoj hauv kev, thiab kev faib ua haujlwm. Thiab lub sijhawm saib ntawm kev thauj mus los, cov khoom lag luam, thiab lwm yam ntaub ntawv ntawm cov khoom tuaj yeem nkag siab lub sijhawm tiag tiag ntawm cov khoom hauv thiab tawm, ua tiav kev tswj xyuas cov khoom muag, thiab pab cov lag luam kom nkag siab cov xwm txheej ntawm cov khoom.

Raws li cov neeg tsim khoom tshiab ntawm cov khoom siv logistics ntse thiab cov kev daws teeb meem, Hebei Woke Hegerls Robotics, raws li AI haiv neeg algorithm muaj peev xwm thiab ib qho chaw nres tsheb rau cov neeg hlau, txuas ntxiv tsim kev lag luam tus qauv ntsuas, muab cov khoom lag luam zoo thiab ntse thiab kev daws teeb meem rau cov neeg siv khoom hauv cov khoom noj thiab dej haus txias saw, nrog rau ntau lub lag luam. Ib qho xwm txheej yog raws li hauv qab no:

1) Intelligent ntom txias cia ntawm ib qho kev lag luam Zhuhai

Cov khoom siv tseem ceeb yog Hegerls txias cia version plaub-txoj kev tsheb thiab hoist.

Qhov project tseem ceeb: Qhov chaw txias txias yog 18m siab, nrog qhov ntsuas kub tsawg kawg ntawm -18 ℃ thiab tshaj 7000 qhov chaw cia. Piv rau stacker cranes, nws txuag tau 35% ntawm kev siv hluav taws xob thiab muaj peev xwm khaws cia ntau dua 25% siab dua. Nws yog hloov tau thiab ua tau raws li qhov xav tau ntawm kev cia khoom ntawm cov neeg thib peb logistics thiab cov chaw muab kev pabcuam rau cov khoom lag luam sib txawv.

2) Lub tsheb plaub-txoj kev cia chaw ntawm ib qho kev lag luam hauv Xinjiang qab zib

Cov khoom siv tseem ceeb: Hegerls plaub-txoj kev tsheb + hoist + ntau lawm palletizing neeg hlau caj npab.

Qhov project tseem ceeb: Nrog rau qhov siab ntawm 22m thiab tshaj 26000 qhov chaw cia, nws tuaj yeem khaws 40000 tons ntawm qab zib tiav. Lub tsev qiv ntawv ntse ntse no yog ib qho tseem ceeb ntawm lub tuam txhab tsim cov cim tshiab ntawm kev tsim khoom ntse ua qauv qhia kev tsim khoom.

3) Lub chaw tsim khoom ntawm ib lub tuam txhab Guangdong

Cov cuab yeej siv tseem ceeb: HEGERLSAMR neeg hlau (kev txawj ntse tuav qhov system).

Cov ntsiab lus tseem ceeb: Txhua AMR tuaj yeem nqa ntau pua kilograms ntawm cov khoom ib zaug, tsis tas yuav muaj kev saib xyuas ntawm qhov chaw. Nws yuav them nws tus kheej thiab tuaj yeem ua haujlwm ib txwm txawm nyob hauv lub teeb dub. Paub txog qhov automation thiab ntse tuav cov ntaub ntawv, ua tiav raws sij hawm thiab raug tuav cov khoom; Muaj peev xwm ua kom tsis txhob muaj kev cuam tshuam zoo heev txo qhov kev pheej hmoo ntawm kev nyab xeeb hauv kev cob qhia; Ntxiv ua tiav kev tswj hwm digital.

Hebei Woke Metal Products Co., Ltd. tseem ua tib zoo saib xyuas qhov kev thov rau cov khoom lag luam ntse ntse hauv tsev thiab txawv teb chaws, tsom mus rau kev txhim kho thiab tsim cov khoom ntse, tsis tu ncua ntxiv dag zog rau nws tus kheej kev tshawb fawb thiab kev tsim kho, thiab tshawb nrhiav ntau dua. txoj hauv kev los tsim tus nqi ntawm cov hlua txias. Kuv ntseeg hais tias nyob rau hauv txoj kev loj hlob yav tom ntej, Hebei Woke yuav nce ntxiv nws cov kev txhawb nqa rau domestic thiab thoob ntiaj teb txias saw hlau ntse warehousing, txhawb cov neeg muas zaub los ntawm kev xav ntawm "smart logistics" thiab tsim kom muaj nuj nqis.

Post lub sij hawm: Dec-14-2023